Features

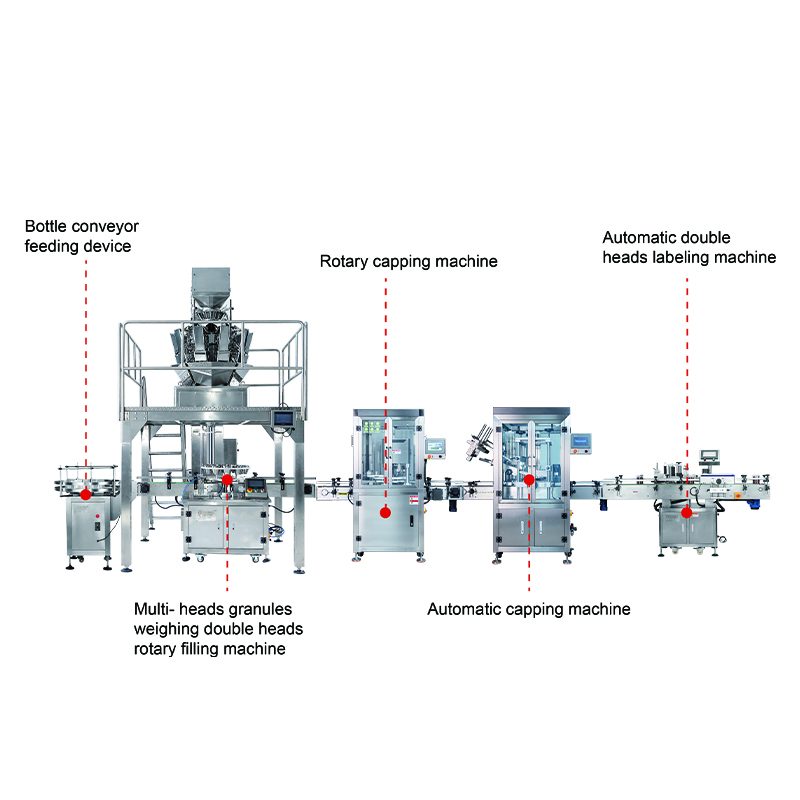

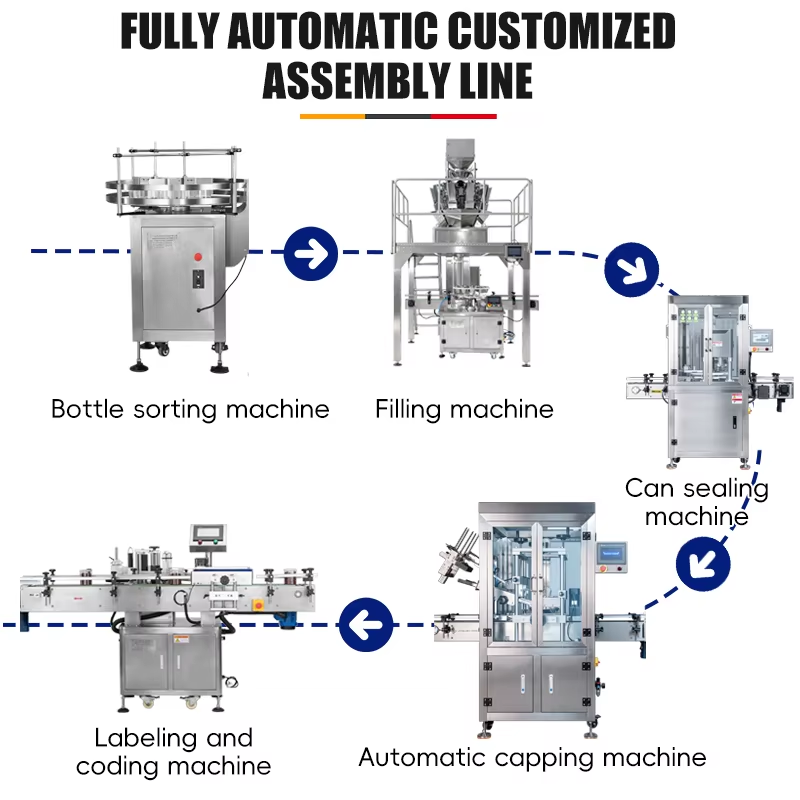

1.Fully automatic conveying, weighing, filling, labeling, and sealing to reduce labor and increase productivity.

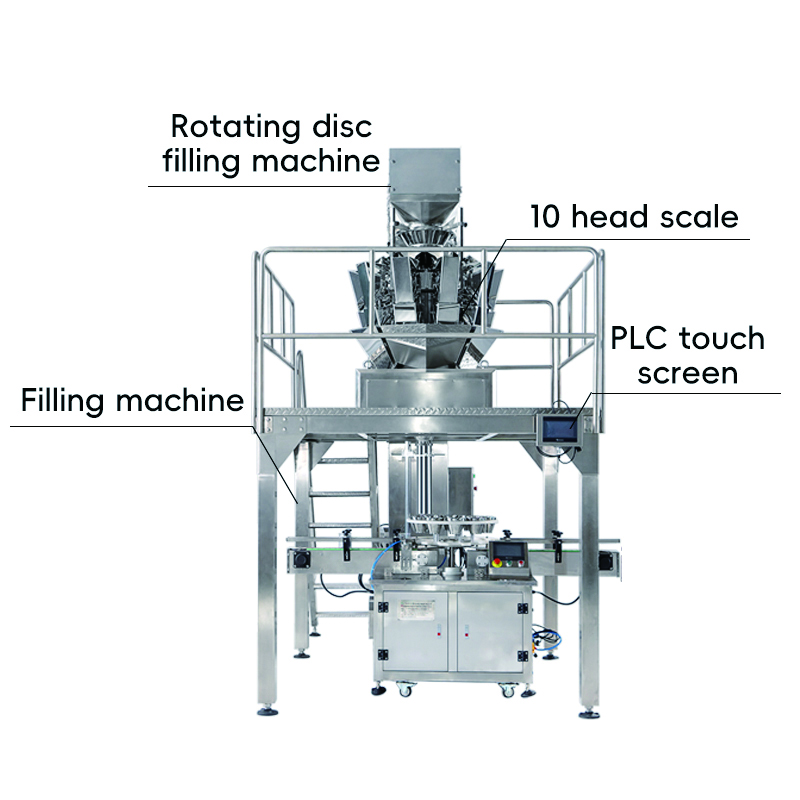

2.SIEMENS PLC control system with a friendly HMI for easy operation and maintenance.

3.Integrated production line including vacuum feeder, filling machine, quantitative weigher, labeling and sealing units.

4.Fast, stable, and reliable performance for continuous operation.

5.Flexible design, customizable with additional stations or equipment integration.

6.Professional pre-sale and after-sale service provided by experienced engineers.

Application

Suitable for weighing and packaging irregular lumps and granules such as peanuts, nuts, seeds, potato chips, puffed foods, coffee beans, rice, wheat and other grains, dried fruits and vegetables, frozen foods (e.g. dumplings), candies, snack foods, and hardware products.

| Automatic Mix Nuts Peanut Cashew Plastic Jar Can Bottle Filling Capping packing Production Line | |

| Type | YL-Granule Automatic Filling Packaging Production Line |

| Application range | Granule material |

| Packing speed | 20-60 cans/min |

| Applicable bottle type | Plastic bottles/cups,Tin cans, Aluminum cans/cups,Paper cans/tubes/cups,Glass bottles/jars |

| Max weight capacity(once) | 10-1000g |

| Weighing Accuracy(g) | ±1-2g |

| Hopper capacity | 2.5L |

| Hopper shape | Double row no memory bucket |

| Main standardized parts | 1.Automatic bottle feeding machine 2.automatic bottle unscrambler 3.automatic feeding and filling machine 4. automatic weighing machine 5. automatic capping machine 6. automatic labeling machine 7. automatic date-printing machine 8. finished bottle collecting machine |

| Drive mode | Stepping motor/servo motor |

| Filling heads | 1 head |

| Weighing heads | 10/14 Heads |

| Options | Linear filling/rotary positioning filling |