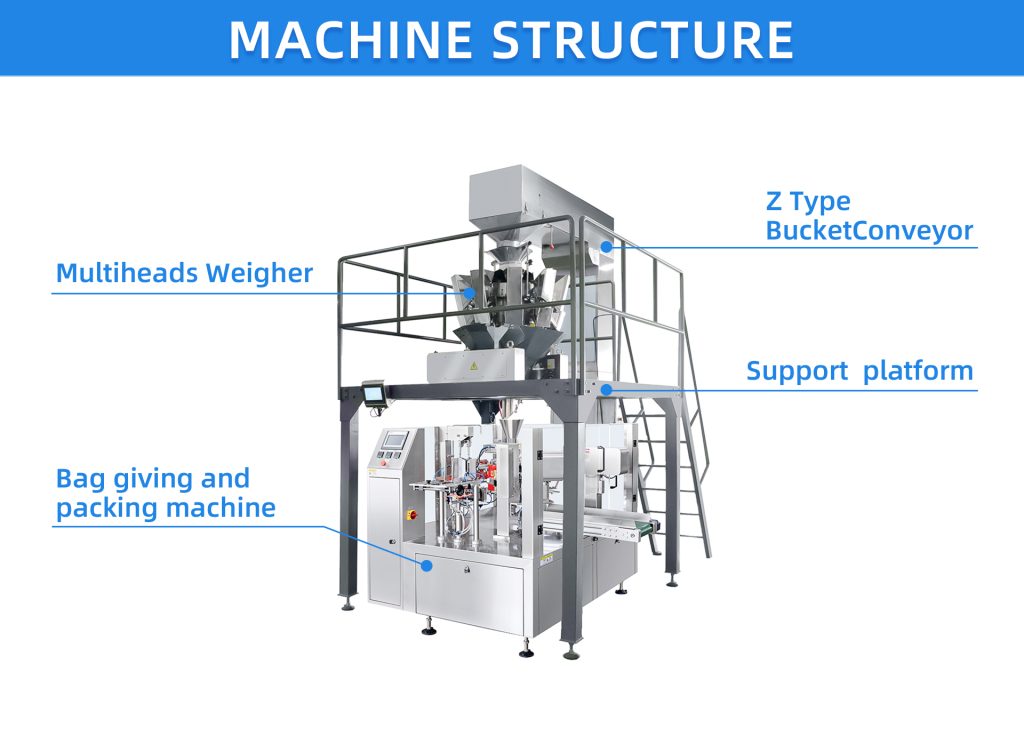

The system automatically completes material feeding, weighing, bag opening, filling, sealing, date printing, and final output. Granules are transported by a Z-type conveyor to a multi-head weigher for accurate dosing, then filled into pre-made bags and sealed by the packaging machine to achieve efficient and stable automatic packaging.

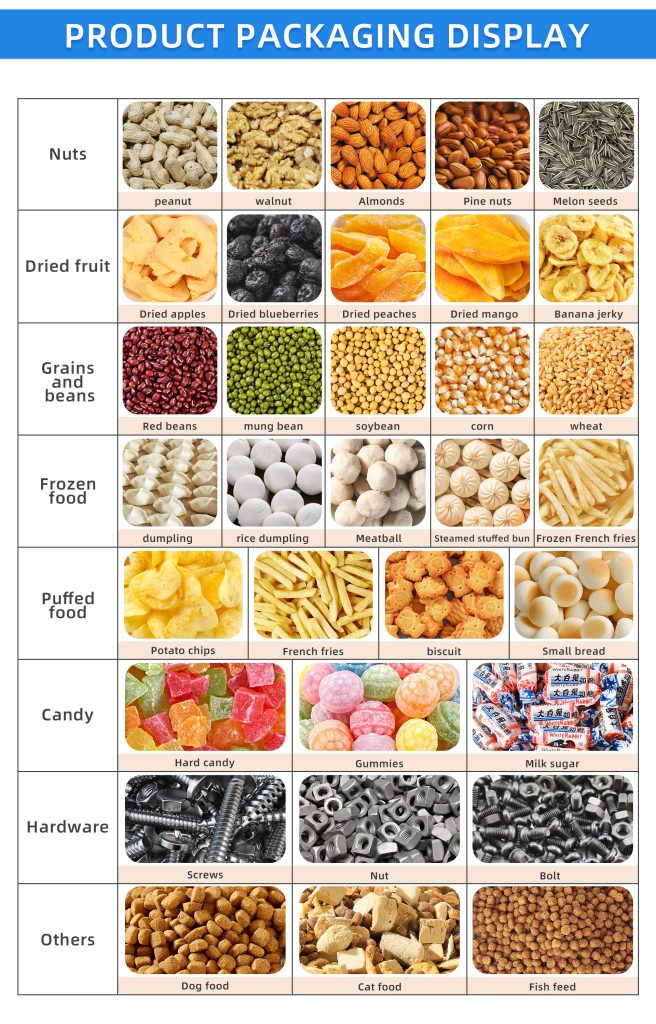

Suitable for packaging various granules and irregular products, including:

peanuts, nuts, melon seeds, cashews, almonds, potato chips, puffed snacks, coffee beans, rice, cereals, dried fruits, vegetables, frozen food, candies, snacks, and small hardware items.

Technical specifications

| Fully Automatic 100g 250g 500g Nuts Peanut Seeds Filling Granule Packaging Machine | |||

| Type | YL-GD8-230/260/300 | ||

| Premade bag size | 90-350mm(L),90-230mm(W) | 90-350mm(L),90-230mm(W) | 90-350mm(L),90-230mm(W) |

| Packing speed | 20-50bags/min | 15-50bags/min | 10-35bags/min |

| Accuracy | ±1g (≤100g) / ± 1%( >100g) according to material | ||

| Fill Range | 10g-500g | 10g-1000g | 10g-2500g |

| Air Consumption | ≤0.8m³/min | ||

| Power supply | 380V/2500W | ||

| Standard 8 Stations workflow | 1.Bag feeding 2.Coding 3.Opening 4.Filling A 5.Reserving 6.Reserving 7.Heat sealing 8.Forming and output conveyor | ||

| Optional Devices | Date coding printer, Air-filling device, Punching device | ||